This page shows ways to build NYC style El structure. Being inspired by the great model structures of Nate Gerstein, Joseph Frank, and Bob Olson, I have set out to build my own! The structure modeled here is based on the city built "dual contracts" design. This type of structure can be found on lines including - Astoria, Flushing, West End, Culver, and IRT lines in the Bronx. This design was very standardized and simplified from previous el construction and is easily adapted, and reduced to O scale - or any scale for that matter. An excellent source of information regarding this type of structure is the book, "Building The New Rapid Transit System of New York City Circa 1915" , published by Xplorer Press.

For this project, we will be using styrene plastic strips and structural shapes that are commercially available. Styrene was chosen here because it is easily cut and there is an excellent variety of shapes and sizes currently available. There are two companies that make styrene, Evergreen and Plastruct. They can be found in most hobby shops. In the event your shop doesn’t have them in stock, they can usually order just what you want.

Cutting these strips and shapes to length in quantity is the key to building the structure, and a tool called "The Chopper II",from Northwest Shortline, makes the job easy. This tool will cut pieces to the same size consistently, making it easy to collect enough parts to build in mass. Remember, when using this tool or any tool, follow the operating instructions and safety precautions carefully.

The best glue to use to join the styrene pieces is Testors liquid cement (or similar product). This liquid will actually melt the pieces together to create a strong joint. When joining dissimilar parts, such as styrene to metal, a "super" glue is used.

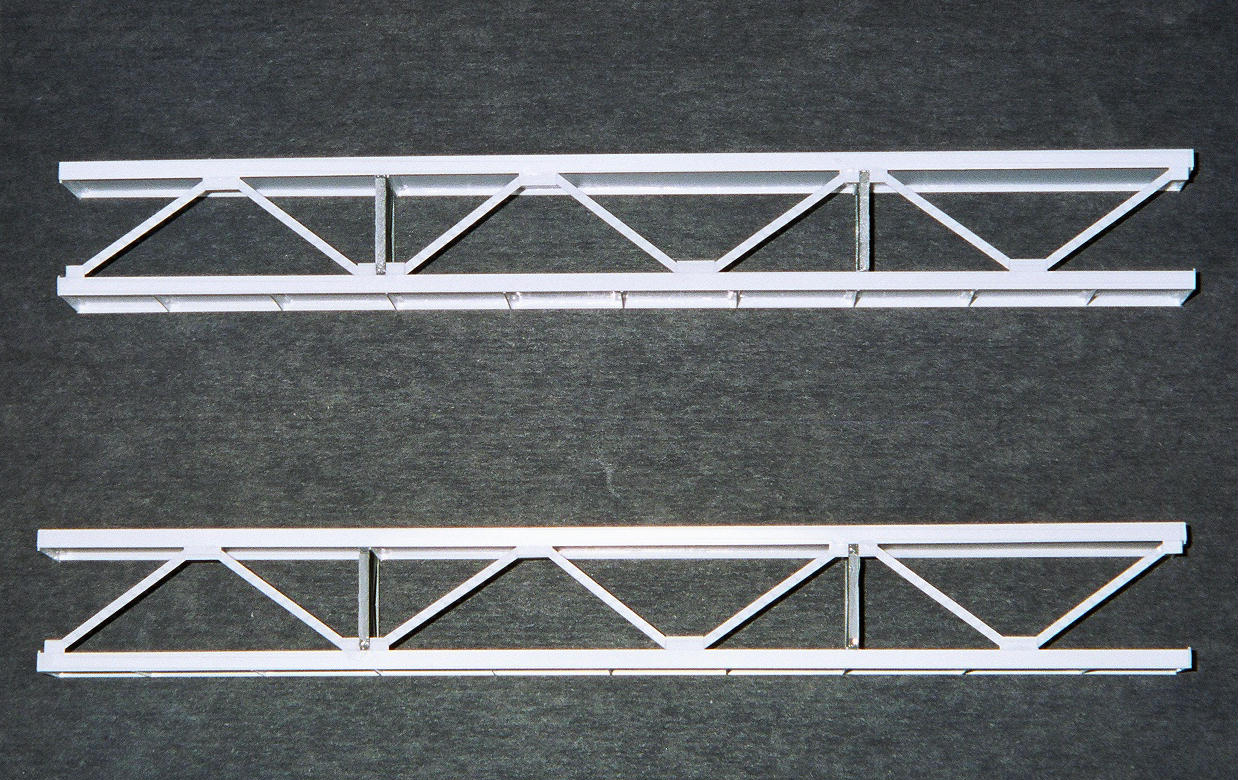

Following the drawings and descriptions used in the book mentioned above, one can scale down the actual dimensions used. For instance, in O scale, the depth of the girders should be a scale 5 feet or 1-1/4 inches. The length works out to 50 scale feet or 12-1/2 inches. To simplify this further, shortening the length to 48 scale feet or 12 inches, you can get more out of the material used and the dimensions figure easier. The clearance under the el should be between 15 to 20 scale feet, but can be less depending on the situation.

The photos on this page can be enlarged by clicking on them.

Cut 8 #268 channel pieces to the fit the width of the .020 styrene sheet used for the web of

the cross girder. Place the center of each at the centerline of the track girders (5 scale

feet apart - center to center) and one at each edge. Then use the # 139 strips for top and

bottom sills to complete the girder.

The upright columns are made of a piece of #90517 I-beam and #268 channel pieces on either

side. The outside channel runs the length of the entire assembly while the inner one and

the I-beam runs from under the cross girder. A corner brace (# CS397) is added to each corner.

Cut 11 #293 angle pieces to fit the width of the #90641 strip used for the web of the

track girders (which is cut to 48 scale feet long).

Use 7 #293 angle pieces to make the cross bracing. Each is 8 scale feet long.

The completed structure (Left).Tools used for this project (Right).

While designing your El, consider whether you want the columns in the street, or at the curb. The difference depends on the width of the street you are modeling. For example, on the West End line, New Utrecht Avenue is only 4 lanes wide and has the columns at the curb, while 86th Street is 6 lanes wide and has the columns in the street. The structure is slightly different depending on this, as well. Also, do you want a streetcar line under the El? Plan this ahead of time.

To get ideas for building your El, examine as many photos as possible. If you live in NYC near an elevated line, walk under it, examining how it is put together. Go through as many NYC Subway books as you can. Look at the track structure. Get an idea of what the catwalk and tie straps look like. How is the third rail placed? How does the structure differ at stations? The pictures contained here and in the book will help to get you started.

Keep in mind, these are just one person’s techniques and ideas. They have come from observing the real thing, and collecting ideas from other more experienced modelers. They may not be the best way to go about this for you. You may find many other ways to come up with an even better looking structure, or better structure to suit your needs. Using your own creativity and ingenuity, you may come up with a better process. These ideas and techniques are to illustrate that building El structure is not all that hard, and can actually be fun and rewarding.

Create Operating 3rd Rail for your Rapid Transit layout.

This page has suggestions and construction techniques for installing 3rd rail and making operating 3rd rail shoes.

We hope you found this article to be informative and helpful. If there are any questions or suggestions please email Steven Olsen

![]()

Created on: 06-12-2002

Updated: 06-12-2021